It is more efficient to operate the chillers at or near full load. The degree of chiller loading was found to be a key factor for efficiency. Although the types of problems uncovered and the level of energy savings may differ significantly from other projects, some of the benefits of detecting and diagnosing problems are expected from the use of MPC for any chilled water plant. Although it is difficult to quantify the energy savings resulting from these problems being remedied, they were likely on the same order as the energy savings from the MPC itself.

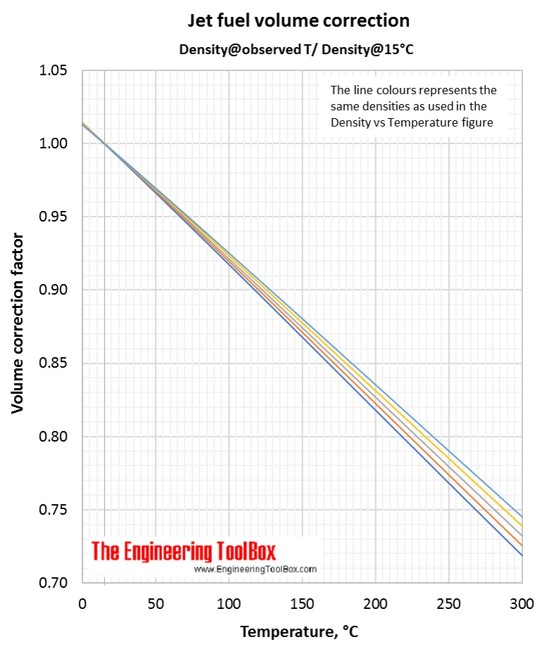

The process of data collection and model development, necessary for any MPC project, resulted in the team uncovering various problems with the chilled water system. This baseline includes control policy improvements that the plant operators learned by observing the earlier implementations of MPC, including increasing the temperature of the water supplied to the chiller condensers from the cooling towers. Measurement control procedures for remeasurement of the process solution in the tank during normal operation can provide data to validate temperature correction = 2.2% relative to a baseline established immediately prior to the period when the MPC was run in its final form. Although not difficult or necessarily time-consuming to run, good practice requires a test plan following demonstrated guidelines. Development of the temperature correction algorithm requires that the measurement process be clearly defined, conditions or limitations specified, and that a temperature-effects test be run.

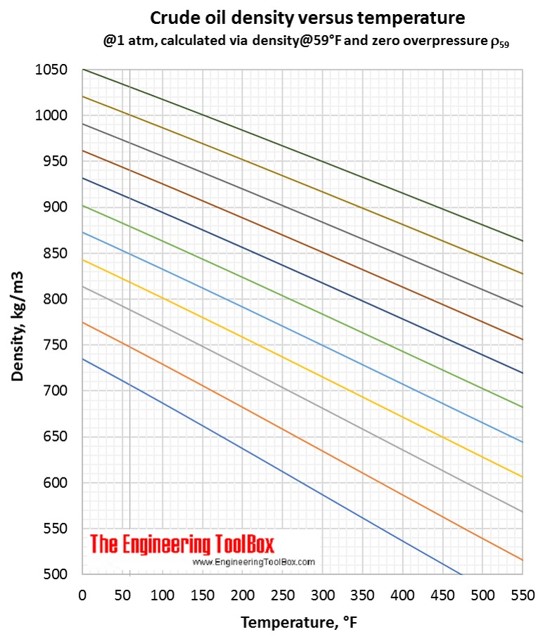

These are representative of the four types of liquid level detection techniques. This paper describes the physical principles of pressure, capacitance probe, sonic reflections, and visual scales. Level measurement devices can be grouped according to four measurement points of reference: tip of probe, response proportional to the length of probe, top of tank, and liquid surface. In addition, the response signal of the sensor and hence the response of the liquid-level detection device may change with temperature. The dimensions of the tank, and the density and level of the liquid it contains vary with temperature. Temperature changes affect volume measurements in several ways.

0 kommentar(er)

0 kommentar(er)